Butane Extraction Safety Standards for Cannabis Facilities

Butane remains one of the most widely used methods for producing potent cannabis concentrates thanks to its efficiency and ability to preserve terpene profiles. Since it is a combustible gas, it requires a solvent-based extraction process. In doing so, operators work with materials that require strict engineering controls and disciplined safety practices.

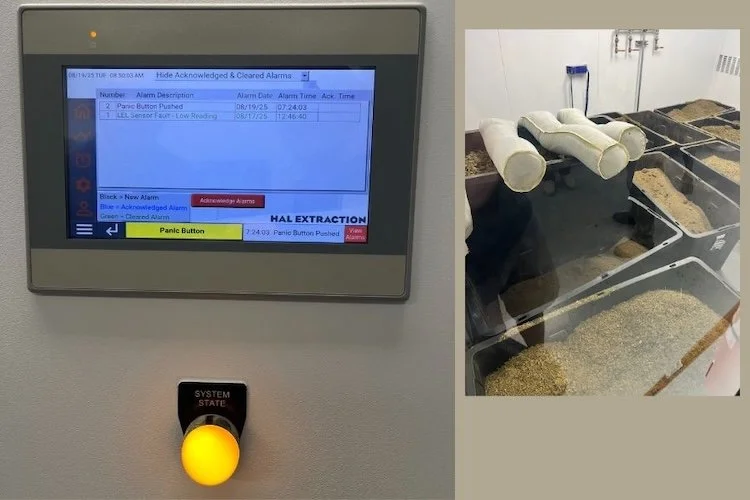

Inside a C1D1 extraction booth, every detail is designed to protect both workers and facilities. But its effectiveness depends on training and adherence to the procedure.

This article outlines the health risks of butane exposure and the steps required to maintain a safe environment.

Understanding Butane and Its Health Risks

As a colorless, naturally odorless hydrocarbon gas, butane becomes flammable when mixed with air at certain concentrations. It has a lower explosive limit (LEL) of 1.6% and an upper explosive limit (UEL) of 8.4%.

It affects the central nervous system, slowing brain activity.

Short-term effects include:

Confusion

Dizziness/lightheadedness

Hallucinations

Headaches

Irritation of the eyes, nose, and throat

Loss of coordination

Nausea

Slurred or distorted speech

If people are regularly exposed to butane, it can lead to long-term effects, including:

Excessive thirst (polydipsia)

Fatigue

Irregular heartbeat

Loss of sense of smell and hearing

Memory loss

Pallor (pale appearance)

Reduced attention span

Stomach ulcers

Butane is not a carcinogen, but some blends can contain small amounts of benzene, a regulated contaminant linked to blood disorders and leukemia.

Safe handling of butane is a cornerstone of both workplace safety and regulatory compliance.

Workplace Safety and Compliance

To keep workers safe, air monitoring, ventilation, and PPE (personal protective equipment) are compliance requirements under OSHA standards. 29 CFR 1910.1200 (Hazard Communication) and 1910.1028 (Benzene Standard) are examples.

C1D1 rooms must have:

Clearly labeled pressurized gases and accessible Safety Data Sheets (SDS)

Explosion-proof equipment and electrical systems

Proper ventilation and continuous air exchange

Regular inspections and maintenance documentation

Maintenance logs, air-monitoring data, and training records are proof that a facility operates to professional standards.

Operator Best Practices

Since butane is heavier than air, it settles near the ground. The gas is stored under pressure in steel cylinders, which must be kept upright, secured, and temperature-controlled.

Conduct routine leak checks and document findings.

Ensure ventilation and exhaust systems are fully operational before starting any extraction run.

Immediately report and log any unusual odors, pressure changes, or exposure symptoms.

Keep all ignition sources outside the booth, and electronic devices are prohibited unless they’re specifically rated for C1D1 use.

Use a gas meter to verify waste is ready for pickup by placing the probe at the bottom of the receptacle, and always calibrate and meter outside of the C1D1 room for accurate readings.

Dispose of Cannabis Waste Responsibly

At Monarch Waste Co., we understand the unique challenges faced by cultivation, manufacturing, dispensary, and testing facilities. That’s why our experts use proprietary rendering processes specifically developed for various waste streams to ensure both compliance and compatibility.

We’ll create a personalized waste management solution and guide your facility through each step of the disposal process. Learn more about how we’re here to support your cannabis facility in achieving safe and efficient waste management practices by contacting us today!